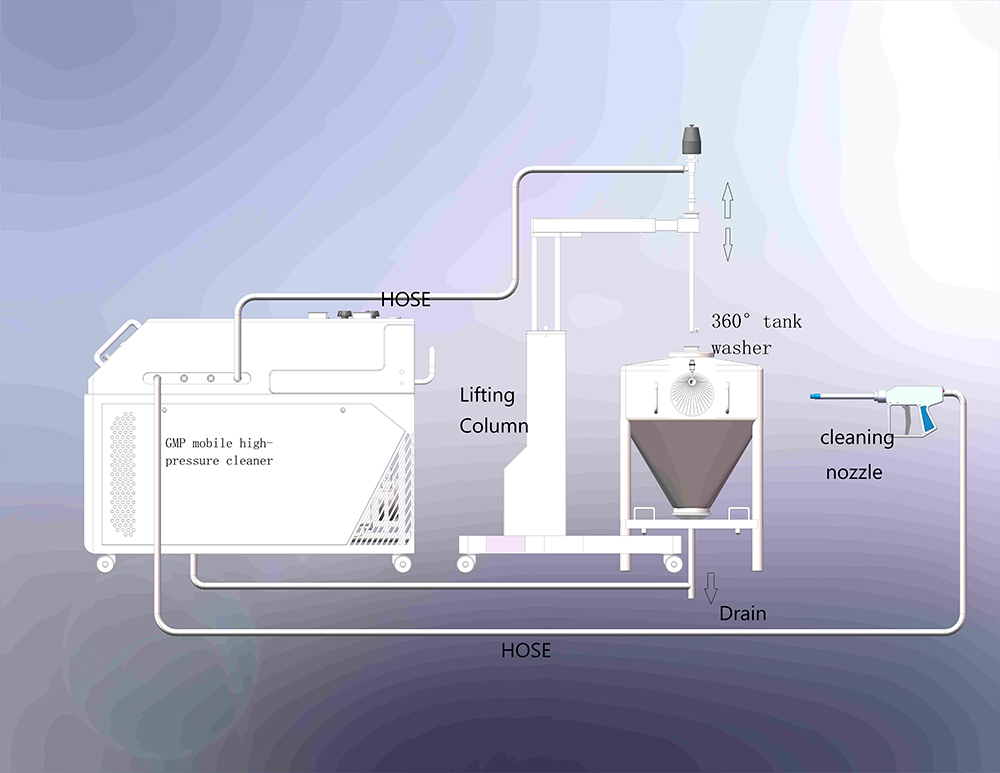

Mobile High-Pressure GMP Cleaning Machine

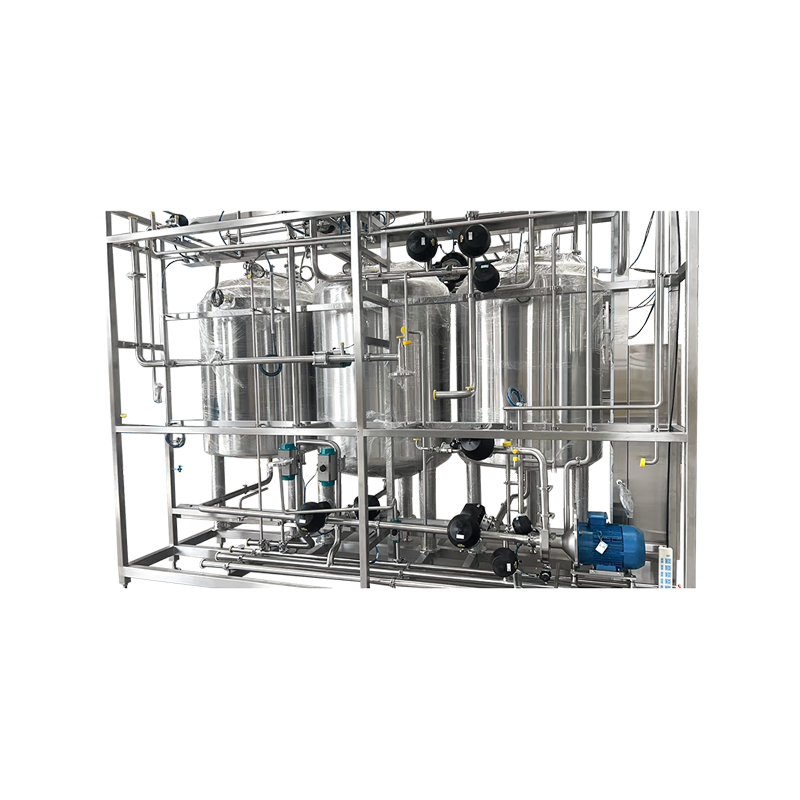

CIP system

The CIP system, short for Cleaning In Place System, also known as an on-site cleaning or in-situ cleaning system, is a technique that allows for the thorough cleaning of equipment interiors without the need to dismantle or move the apparatus. It utilizes high-temperature, high-concentration cleaning solutions to effectively clean surfaces that come into contact with food. The principle behind it involves using centrifugal pumps to force the cleaning solution through the equipment and pipelines in a continuous cycle. This process combines physical scrubbing (through the flow and spraying of the cleaning solution) and chemical reactions (between the chemicals in the cleaning solution and the contaminants), thereby removing dirt, microorganisms, and other residues from the equipment surfaces, achieving both cleaning and disinfection.

Components:

Cleaning Solution Storage Tanks: Used for storing different types of cleaning solutions such as acidic, alkaline solutions, and water. Depending on the cleaning process requirements, various cleaning solutions are injected into the system in specific proportions and sequences.

Centrifugal Pumps: Provide the necessary power for circulating the cleaning solution, ensuring it flows at an appropriate speed within the equipment and pipelines to guarantee effective cleaning.

Pipeline System: Connects all equipment and components, delivering the cleaning solution to the areas that require cleaning and allowing the solution to return to the storage tanks.

Cleaning Nozzles: Installed inside the equipment, these nozzles spray the cleaning solution onto the equipment surfaces in a specified manner to enhance cleaning efficiency. Their design and placement are optimized based on the shape of the equipment and cleaning requirements.

Control System: Automates the control of the cleaning process, including setting and adjusting parameters such as the temperature, concentration, flow rate of the cleaning solution, and cleaning duration, ensuring stability and consistency throughout the process.

Applications:

Food and Beverage Industry: On beverage production lines, the CIP system can regularly clean equipment like fillers, fermenters, and pipelines, preventing microbial growth and cross-contamination between products, thus ensuring product quality and safety. For example, in breweries, the fermentation tanks and pipelines are cleaned and disinfected using the CIP system, effectively avoiding contamination by miscellaneous bacteria and preserving the flavor and quality of beer.

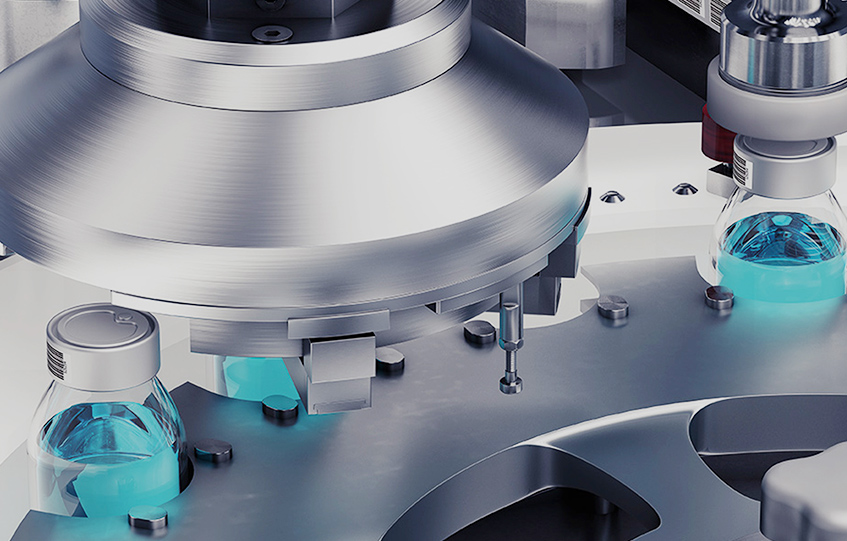

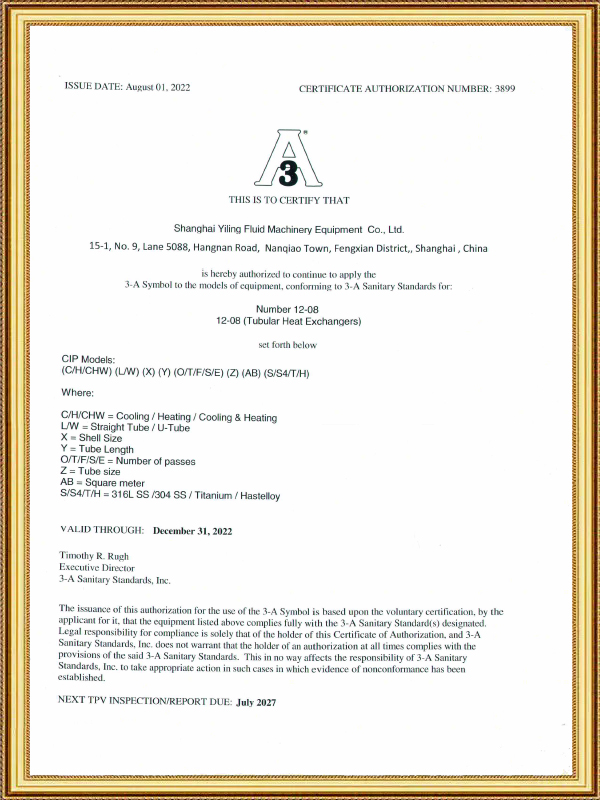

Pharmaceutical Industry: Equipment cleanliness standards in pharmaceutical manufacturing are extremely stringent. The CIP system meets these high standards for equipment cleaning and sterilization required by pharmaceutical processes. It thoroughly cleans reactors, concentrators, infusion pipelines, and other equipment, preventing drug residue and cross-contamination, ensuring the purity and quality of medicines.

Dairy Industry: Throughout the milk processing chain, from storage tanks to processing equipment and filling machines, maintaining high levels of hygiene is essential. The CIP system enables rapid and efficient cleaning and disinfection of equipment between production batches, preventing milk spoilage and microbial contamination, thereby extending product shelf life.