Electric diaphragm valves have become a core component in pharmaceutical fluid-handling systems due to their superior hygiene, precise flow control, and suitability for cleanroom operations. As modern pharmaceutical manufacturing demands higher levels of automation, sterility, and validation, electric diaphragm valves play a crucial role in ensuring safe, contamination-free processes. This article explores how these valves function, where they are applied in pharmaceutical production, and what factors to consider when selecting them.

What Is an Electric Diaphragm Valve and How Does It Function?

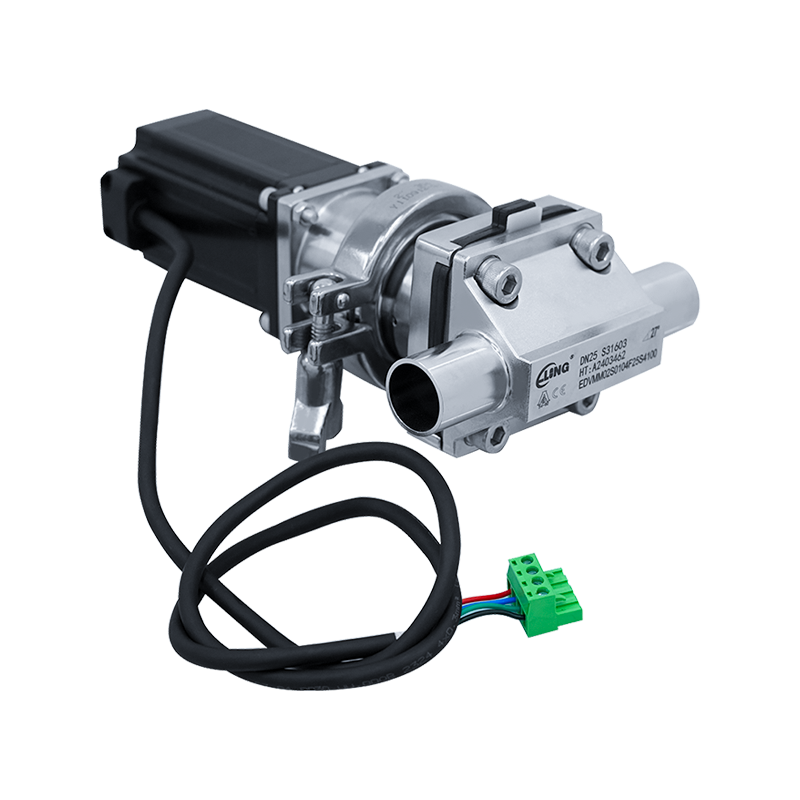

An electric diaphragm valve is a control valve that uses an electric actuator to move a flexible diaphragm up or down to regulate fluid flow. Unlike traditional valves with metal contact surfaces, diaphragm valves use a polymer diaphragm that isolates the fluid path from the actuator and mechanical components. This eliminates contamination risks and ensures exceptionally hygienic operation, making them ideal for pharmaceutical processes that require sterile, ultra-clean conditions.

Core Functional Components

- Valve Body – often made of stainless steel or high-grade plastic, designed for hygienic and corrosion-free performance.

- Diaphragm – a flexible elastomer that seals the fluid path and prevents contamination.

- Electric Actuator – provides automated control with high precision, enabling integration with modern control systems.

Electric diaphragm valves are typically used for regulating sterile liquids, pure water, process chemicals, and cleaning agents in pharmaceutical production lines. Their contamination-free design makes them one of the safest valve options for high-purity environments.

Where Are Electric Diaphragm Valves Used in Pharmaceutical Processes?

In pharmaceutical facilities, electric diaphragm valves are installed in process water systems, product transfer pipelines, filtration loops, and clean-in-place (CIP) and sterilize-in-place (SIP) systems. Each application requires extremely high reliability and compliance with hygiene standards.

Typical Pharmaceutical Applications

- Purified Water (PW) and Water for Injection (WFI) Systems – ensuring sterile and particle-free fluid flow.

- Bioreactors and Fermentation Lines – regulating nutrient feed, buffer solutions, and cell culture fluids.

- Filtration and Chromatography Processes – maintaining precise and consistent fluid flow rates.

- CIP/SIP Systems – allowing safe flow of cleaning and sterilization media without risking contamination.

- Aseptic Filling and Packaging Lines – offering sterile control for sensitive downstream processes.

These applications require stable performance, high precision, and absolute reliability, which electric diaphragm valves are designed to deliver. Their ability to integrate with digital control systems makes them a preferred choice for modern automated pharmaceutical plants.

What Advantages Do Electric Diaphragm Valves Offer for Pharma Production?

Electric diaphragm valves are selected in pharmaceutical facilities because of their ability to maintain sterile boundaries, provide accurate flow control, and meet strict regulatory requirements. Their hygienic design and smooth internal surfaces minimize dead zones and reduce the risk of microbial growth.

Performance Benefits

| Advantage | Description |

| Hygienic Operation | No metal contact with the product stream; ideal for sterile processes. |

| Automation Compatibility | Electric actuators integrate with PLCs and digital control systems. |

| Dead-Zone-Free Design | Minimizes areas where contaminants can accumulate. |

| Easy Validation | Smooth internal surfaces simplify cleaning and compliance checks. |

| Chemical Resistance | Resistant to acids, alkalis, and cleaning agents used in CIP processes. |

These advantages make electric diaphragm valves indispensable for processes where contamination control, sterility, and precision are non-negotiable.

How Do Electric Diaphragm Valves Support Regulatory Compliance?

Pharmaceutical manufacturing operates under strict regulatory frameworks, including GMP, FDA, and USP standards. Electric diaphragm valves are designed to meet these requirements by providing traceability, cleanability, and documentation. Their construction materials are compatible with pharmaceutical-grade requirements, making validation straightforward and repeatable.

Compliance-Driven Features

- Stainless steel 316L valve bodies with low ferrite levels for hygienic purity.

- FDA- and USP-compliant elastomer diaphragms to ensure biocompatibility.

- Electropolished surfaces with Ra values suitable for sterile operations.

- Documentation packages including material certificates and validation reports.

These features help pharmaceutical facilities ensure that all fluid-contact components meet required standards and support audit readiness at all times.

How to Select the Right Electric Diaphragm Valve for Pharmaceutical Applications?

Choosing the appropriate electric diaphragm valve depends on the specific process conditions, including fluid type, pressure, temperature, sterility requirements, and level of automation. Each factor influences the valve’s lifespan, performance, and suitability for a particular production line.

Selection Factors to Consider

- Material Compatibility – ensure the diaphragm and body material can withstand process fluids and cleaning agents.

- Actuator Type – choose based on required precision, control signal compatibility, and automation level.

- Flow Requirements – the valve size and flow characteristics must match the process needs.

- Temperature and Pressure Range – must align with product, steam sterilization, or CIP conditions.

- Certifications – look for FDA, USP Class VI, and GMP-compliant designs.

By evaluating these criteria, engineers can select a valve that supports process efficiency, sterility assurance, and long-term reliability.

How Do Electric Diaphragm Valves Improve Production Efficiency?

Automation is crucial in modern pharmaceutical manufacturing, and electric diaphragm valves enable precise control over critical processes. Their compatibility with digital monitoring systems allows real-time feedback, remote operation, and accurate adjustments of fluid flow, all of which contribute to improved quality control and reduced downtime.

Efficiency Enhancements

- Reduced human error through automated valve actuation and monitoring.

- Consistent and repeatable process conditions during long production cycles.

- Fast response time for precise adjustments in sterile processes.

- Improved batch-to-batch consistency through automated control systems.

Overall, electric diaphragm valves contribute significantly to continuous production, reduced operational costs, and improved pharmaceutical product quality.