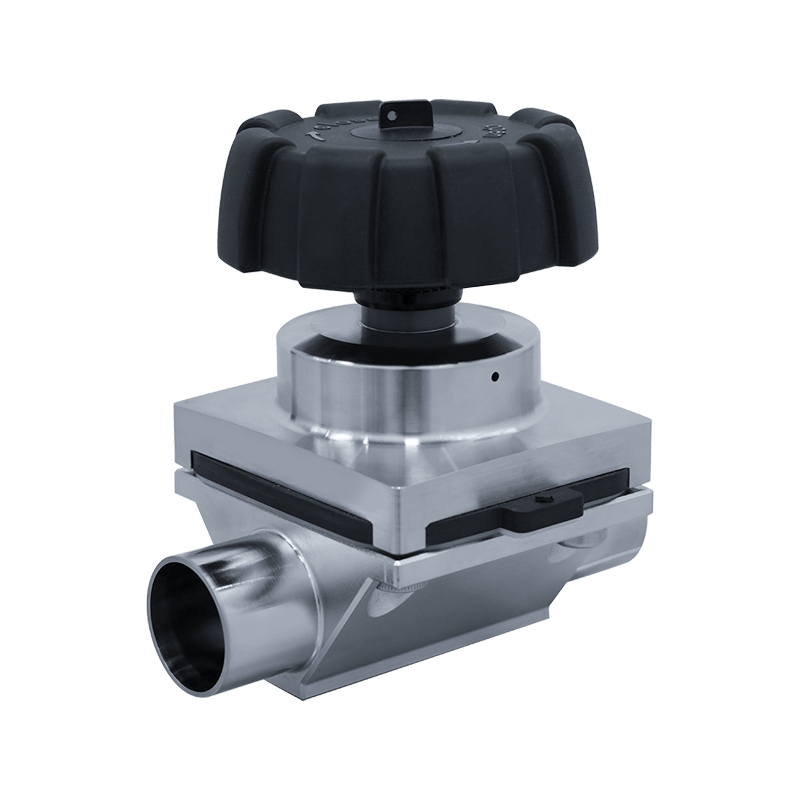

When it comes to handling corrosive or hazardous fluids, selecting the right valve can significantly influence both process safety and system longevity. A manual diaphragm valve is often a strong candidate in such environments because of its simple yet highly effective design. With no complex actuation components and a sealed, linear flow path, these valves offer both operational safety and ease of maintenance, which are crucial when dealing with aggressive media.

One of the defining features of a manual diaphragm valve is the physical separation it creates between the fluid and the mechanical parts of the valve. The diaphragm acts as a flexible barrier, ensuring that the process fluid never comes into contact with the stem or other moving components. This separation is particularly valuable when the fluid being handled is toxic, abrasive, or chemically reactive, as it reduces the risk of internal contamination or mechanical corrosion.

Material selection again plays a key role in this context. Diaphragms made from chemically resistant materials such as PTFE or Viton, combined with valve bodies constructed from stainless steel, PVDF, or polypropylene, provide the durability required for harsh operating conditions. A manual diaphragm valve configured with the right materials can reliably contain substances like acids, solvents, and caustic solutions without degradation or leakage. This makes them a smart, practical option in industries such as chemical processing, water treatment, and mining.

Another advantage is the valve's ability to deliver consistent sealing even after repeated use. The manual operation mechanism allows the user to control the degree of closure with precision, which minimizes wear on the diaphragm and extends the service life of the valve. For corrosive or hazardous fluids, this precise control also reduces the chances of pressure surges or accidental discharges, which can be safety hazards or cause damage to downstream equipment.

For system designers and plant operators, one of the most appreciated aspects of the manual diaphragm valve is its predictability in challenging environments. Without reliance on external power or compressed air, these valves continue to function in power-outage scenarios or isolated installations, making them a dependable solution for remote or safety-critical applications. That reliability, paired with a compact structure and relatively low maintenance cost, adds up to a high-performance solution for fluid control challenges.

We’ve supplied manual diaphragm valves to customers working with everything from hydrochloric acid to sodium hypochlorite, and in each case, thoughtful material pairing and proper valve sizing were key to long-term success. Our experience shows that with the right configuration, these valves deliver exceptional containment and performance, even under continuous exposure to aggressive fluids.

In summary, the manual diaphragm valve proves itself time and again as a safe, reliable, and cost-effective option for corrosive or hazardous fluid systems. Its unique design, combined with smart material choices and manual control simplicity, gives operators peace of mind and process engineers a flexible tool to meet demanding specifications. For buyers seeking both performance and assurance in tough conditions, this type of valve is not just an option—it’s a proven solution.