In industries where precision, safety, and hygiene are non-negotiable, the ability to collect samples without contamination is of critical importance. Whether in pharmaceuticals, food and beverage, biotechnology, or chemical processing, sampling is essential for quality control, process monitoring, and regulatory compliance. However, traditional sampling methods often expose products to contamination risks or environmental hazards. This is where the sealed sampling valve comes into play. But what exactly is a sealed sampling valve, and why has it become such a vital tool in modern industries?

What Is a Sealed Sampling Valve?

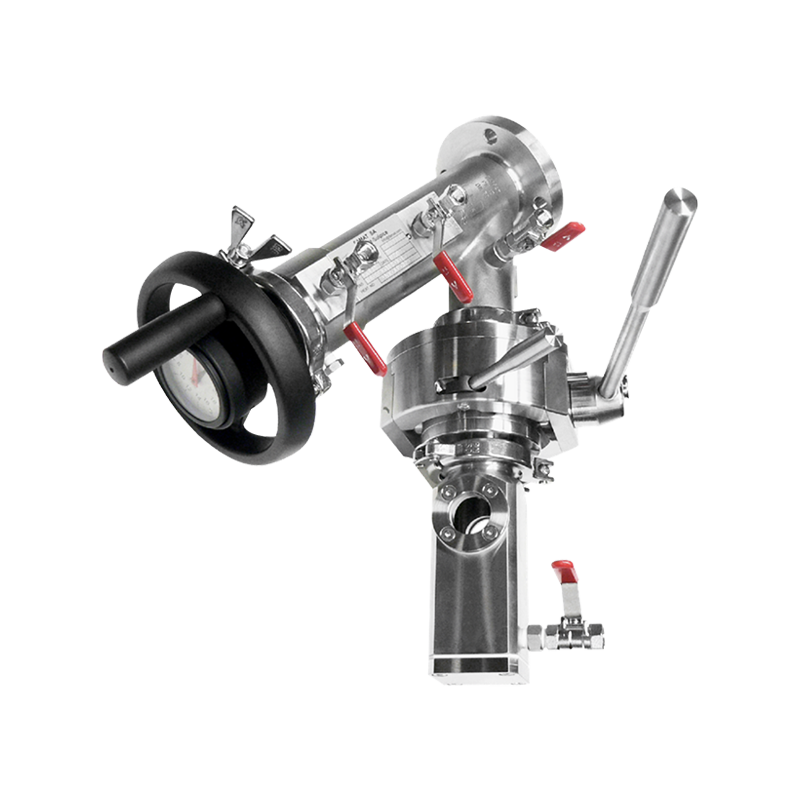

A sealed sampling valve is a specialized valve designed to extract liquid, gas, or powder samples from a process system without exposing the product to outside contaminants or allowing leakage into the environment. Unlike standard valves, sealed sampling valves are engineered to maintain a closed, sterile, and leak-free environment, ensuring that the collected sample is a true and accurate representation of the process stream.

The valve’s design usually includes:

A tight sealing mechanism to prevent leaks.

A flushing system to clean the valve between samples.

Materials resistant to corrosion and chemical attack, such as stainless steel.

Safety features that protect both the product and the operator.

How Does a Sealed Sampling Valve Work?

The functionality of a sealed sampling valve depends on its application, but the process generally involves:

Sterile Preparation – The valve is flushed with steam, water, or cleaning agents to remove any contaminants.

Controlled Opening – The valve opens just enough to allow a small, measured quantity of product to pass through.

Sample Collection – The sample flows into a sterile container, bag, or vial, ensuring no exposure to the external environment.

Automatic Resealing – Once the sample is taken, the valve reseals to maintain the integrity of the process line.

This process minimizes contamination, ensures safety, and provides highly reliable sample data.

Why Are Sealed Sampling Valves Important?

The importance of sealed sampling valves lies in the balance between safety, quality, and compliance. Some of the key reasons include:

Product Integrity: Prevents outside air, microbes, or particles from contaminating sensitive products like pharmaceuticals or beverages.

Operator Safety: Protects workers from hazardous chemicals, high pressure, or extreme temperatures.

Accurate Quality Control: Ensures that test results reflect the true state of the product inside the process line.

Regulatory Compliance: Many industries are legally required to maintain sterile or safe sampling practices.

Environmental Protection: Prevents harmful materials from leaking into the atmosphere or surrounding workspace.

Without sealed sampling valves, companies risk product recalls, worker injuries, and environmental violations.

Which Industries Use Sealed Sampling Valves?

The versatility of sealed sampling valves makes them indispensable in multiple sectors:

Pharmaceuticals

Critical for collecting sterile samples of vaccines, injectable drugs, or other sensitive products.

Food and Beverage

Ensures hygienic sampling of dairy products, beer, juices, and sauces without spoilage.

Chemical and Petrochemical

Protects operators when sampling corrosive, flammable, or toxic chemicals.

Biotechnology

Maintains sterile environments in fermentation processes or cell culture production.

Water Treatment

Allows safe sampling for microbial and chemical analysis of treated water.

In each of these industries, sealed sampling valves play a central role in ensuring safe, compliant, and efficient operations.

What Are the Key Benefits of Using Sealed Sampling Valves?

Sealed sampling valves offer a range of advantages over conventional methods:

Enhanced Sterility: Eliminates contamination risks, essential in sterile production lines.

Consistency and Accuracy: Provides reliable and repeatable samples for analysis.

Reduced Waste: Only a small amount of product is needed for each sample.

Improved Safety: Shields operators from exposure to harmful or high-pressure substances.

Durability: Built from robust materials that withstand harsh operating conditions.

Ease of Cleaning: Many valves are designed for CIP (clean-in-place) or SIP (sterilization-in-place) systems.

These benefits make sealed sampling valves not just a convenience, but a necessity in industries where errors are costly.

What Challenges Exist in Using Sealed Sampling Valves?

Although highly effective, sealed sampling valves are not without limitations:

Cost: Advanced valve systems can be expensive to purchase and install.

Maintenance: Regular cleaning and inspection are required to maintain sterility and function.

Training: Operators must be trained to use the valves correctly, ensuring proper sample collection.

Customization Needs: Different processes may require tailored valve designs, which can increase lead times.

Despite these challenges, the long-term benefits of safety, accuracy, and compliance outweigh the drawbacks.

How Do Sealed Sampling Valves Support Sustainability and Compliance?

In today’s environmentally conscious and highly regulated world, sealed sampling valves play a strategic role:

Reduced Environmental Risk: Prevents accidental release of hazardous substances.

Efficient Resource Use: Minimizes waste during sampling.

Regulatory Alignment: Meets strict standards such as FDA, GMP, or ISO requirements.

Worker Well-Being: Improves occupational health and safety practices.

By protecting both people and the environment, sealed sampling valves align industrial processes with global sustainability goals and legal obligations.

Final Thoughts: Are Sealed Sampling Valves Worth the Investment?

The answer is a resounding yes. Sealed sampling valves are more than just pieces of equipment—they are guardians of safety, quality, and reliability in modern industry. They protect sensitive products from contamination, ensure accurate sampling for quality control, safeguard operators, and help companies meet regulatory and environmental standards.